|

|

Posted - October 02 2016 : 4:19:21 PM Posted - October 02 2016 : 4:19:21 PM

|

So, I have an open-frame motor Mantua Pacific. Yesterday, I finally got around to cleaning my track and trying to test it. Unfortunately, it didn't want to run. It did not seem to be getting left-hand power. I dispensed with the makeshift pickups I made before I got a hold of a matching tender to remove any complication. And I tried re-doing the connection between the wire going to the tender, and the motor.

During this, I managed to cause the left-hand-side brush to pop loose. I got it back in, but the model still doesn't really run. It takes turning the power to 100 to get the motor to even try turning. Did I kill it or do I just suck at soldering?

Feedback-hungry attention w****

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 02 2016 : 5:30:22 PM Posted - October 02 2016 : 5:30:22 PM

|

Make sure everything is clean. Sometimes the tender to motor wire can get loose. Make sure the brush makes full contact as well.

" Heck with counting 'em rivets, TRAINS ARE FOR FUN! Not called the Mad Scientist for nothing either!"

|

Country:  USA ~

Posts: 3145 ~

Member Since: May 07 2007 ~

Last Visit: April 04 2024 USA ~

Posts: 3145 ~

Member Since: May 07 2007 ~

Last Visit: April 04 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 02 2016 : 6:21:37 PM Posted - October 02 2016 : 6:21:37 PM

|

Things seem to be clean, but I'll make doubly sure. I know that the wire is firmly connected on the tender end... what I have my doubts about is the solder joint at the motor end since I did that myself.

Feedback-hungry attention w****

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 02 2016 : 9:51:44 PM Posted - October 02 2016 : 9:51:44 PM

|

Are you able to post pictures of what you are talking about. It may help us in determining what is wrong...

Sean

"If everything seems under control, you're not going fast enough!" - Mario Andretti!

|

Country:  USA ~

Posts: 1729 ~

Member Since: June 15 2011 ~

Last Visit: June 26 2021 USA ~

Posts: 1729 ~

Member Since: June 15 2011 ~

Last Visit: June 26 2021

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 02 2016 : 11:13:24 PM Posted - October 02 2016 : 11:13:24 PM

|

Ok, Train repair tech here. Lets do some simple checks. First, open the engine up, and take your power leads from the track, and touch them to the Brush arms. If it still takes full power to turn it over, then there are two possible issues - binding bearings or drivetrain, or the magnet is shot. If you can turn the motor armature over easily, it's probably not that. Could be the drivetrain is binding, too. Eliminate either one. Then, touch a small steel screwdriver to the magnet, and judge how much effort it takes to pull it away. If barely any, the magnet is too weak to generate enough electrical energy. You can compensate ( and test this ) by attaching a strong permanent magnet to one end of the motor's Alnico magnet. Then touch the transformer power wires to the bursh arms again. if it really starts running, then it's the magnet. Sometimes those fake magnets lose their magnetism over time, and the only way to fix it is to replace it.

By bypassing your wire soldering, this will test the motor right at the brushes, and determine if it's something directly with the motor bad ( windings, magnet, bearings ), or not, then it COULD be your soldering. But it's best to always check directly at the motor first, then work back down the electrical path to the wheels and axles. Step, step, step, it's not hard to troubleshoot, once you know what to look for. There isn't much - wiring, magnetism, electrical path, dirt. How clean are your brushes? If they get a build-up of carbon on them, carbon WILL insulate, you need to clean them with alcohol to get any carbon residue off them. If the armature copper pads are black, you need to clean them. These motors are pretty simple, but there are 4 or 5 things you need to check to troubleshoot them. Good luck, and report back on what you found.

Jerry in VA

" When life throws you bananas...it's easy to slip up"

|

Country:  USA ~

Posts: 3974 ~

Member Since: January 04 2009 ~

Last Visit: January 11 2019 USA ~

Posts: 3974 ~

Member Since: January 04 2009 ~

Last Visit: January 11 2019

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 03 2016 : 09:10:22 AM Posted - October 03 2016 : 09:10:22 AM

|

Before you apply power to anything, make sure nothing is jammed.

Sean

"If everything seems under control, you're not going fast enough!" - Mario Andretti!

|

Country:  USA ~

Posts: 1729 ~

Member Since: June 15 2011 ~

Last Visit: June 26 2021 USA ~

Posts: 1729 ~

Member Since: June 15 2011 ~

Last Visit: June 26 2021

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 03 2016 : 8:20:58 PM Posted - October 03 2016 : 8:20:58 PM

|

Here is are steps to troubleshoot:

1. Check that the magnet is still strong. Use a screwdriver see how hard it is to pull it off of the magnet. If the magnet is weak, that's your issue.

2. Remove the motor from the engine. Attach track power( or any source of power, like a 9v battery) to the brushes. If it dosen't run, the motor has issues.

3. Try to roll the chassis without the motor down the track with your hand. It should be pretty free rolling. If it is stuck, or you feel like something is grinding, stop.

4. Attach the motor back onto the chassis. Take power from the track and attach it to the motor brushes. all the gears and wheels should be spinning. If not, stop here.

5. Now remove the wires that were from the power source to the motor brushes, and place the chassis with motor and tender on the track, with the motor wired correctly. The chassis and tender should run. If not stop here.

6. Add the shell back on and the engine should run. If not, stop here.

NOW REPLY AND TELL US WHICH STEP YOU GOT STUCK ON/STOPPED.

Make sure that nothing that shouldn't be there is under the shell.

SEND PICS IF YOU CAN

As a fail safe, you could disassemble everything and rebuild the kit.

If I can't fix it, I can fix it so it can't be fixed.

Edited by - trainman280 on October 03 2016 8:23:29 PM

|

Country:  USA ~

Posts: 105 ~

Member Since: March 16 2015 ~

Last Visit: March 22 2023 USA ~

Posts: 105 ~

Member Since: March 16 2015 ~

Last Visit: March 22 2023

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 04 2016 : 12:46:32 AM Posted - October 04 2016 : 12:46:32 AM

|

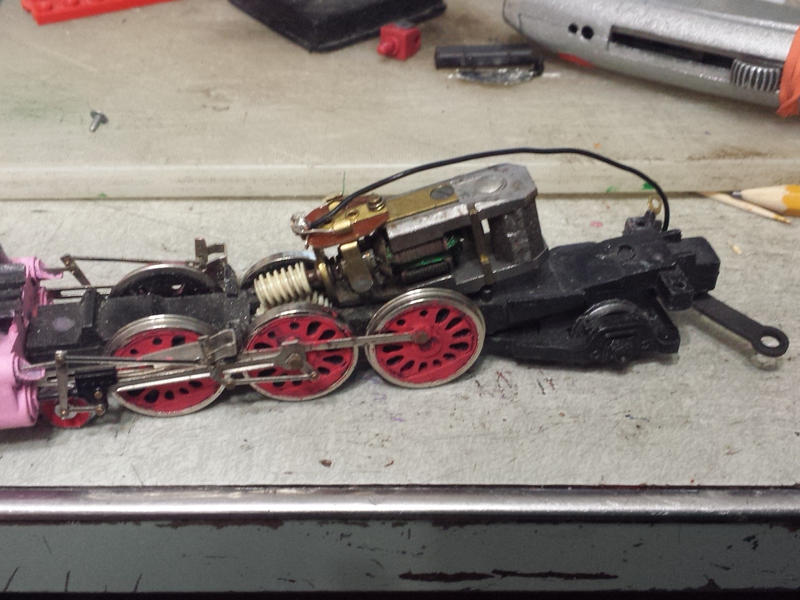

Here's a picture:

I have conducted some tests. The wheels and rods aren't binding, I have confirmed that much. I have also tested the magnet. It was able to dangle my small screwdriver (1 1/4" x 5/8" butt) without dropping it, and I had to employ a little effort to pull the screwdriver away - the magnet definitely wanted to hold onto it.

You will note what I have not tested.

Justin, trainman..

This may come as a shock to you, but not everybody uses a power cable with separate leads on each wire. Many of us use plug-and-play terminal tracks, myself included. You both just assumed I would have such leads, which is unhelpful and slightly irritating

Feedback-hungry attention w****

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 04 2016 : 01:32:39 AM Posted - October 04 2016 : 01:32:39 AM

|

| Well I would recommend getting some separate leads as quick as possible. Without them you're really just of luck in the troubleshooting aspect of things. They are very helpful when doing any sort of repair work. Also, leads are extremely common and very necessary when it comes to repair. They, like me just assume that everyone has a set. No need to be <what seems as> hostile towards these people wanting to help you. If you can't afford a set then your best bet would to be to use your plug in play set and power the track then find someway to attach a wire to each of the rails. You could probably tape some down or take a piece of extra track and solder some wires to it.

|

Country:  USA ~

Posts: 412 ~

Member Since: October 23 2015 ~

Last Visit: June 12 2022 USA ~

Posts: 412 ~

Member Since: October 23 2015 ~

Last Visit: June 12 2022

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 04 2016 : 06:55:05 AM Posted - October 04 2016 : 06:55:05 AM

|

quote:Before you apply power to anything, make sure nothing is jammed.

Originally posted by Mustangs_n_Trains - October 03 2016 :  09:10:22 AM

|

That can be awfully sticky and gouky if strawberry Jam. I remember when the spaceballs radar got jammed. What a mess.

frank

toptrain

" It's a Heck of a Day " !!!

|

Country:  USA ~

Posts: 7504 ~

Member Since: August 07 2008 ~

Last Visit: February 24 2024 USA ~

Posts: 7504 ~

Member Since: August 07 2008 ~

Last Visit: February 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 04 2016 : 07:36:32 AM Posted - October 04 2016 : 07:36:32 AM

|

Didn't mean to be hostile. Sorry

Now, I'm dead sure we have testing leads somewhere in the garage. It just... it bugs me somehow to have it assumed I'm using a specific kind of cable to power my track.

Feedback-hungry attention w****

Edited by - ZeldaTheSwordsman on October 04 2016 10:26:39 AM

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 04 2016 : 2:16:52 PM Posted - October 04 2016 : 2:16:52 PM

|

On these types of motor mounts (and I have more than a few of them) I have noted that when

the motor is mounted to the frame, the worm gear can press down on the gear too hard and

cause the motor to not be able to turn I have had to shim the motor to move the worm gear

up a little from the gear so that they move a little more free.

Step 1 is to turn the motor by hand to be sure that it turns freely.

Step 2 is to roll the frame/drive assembly on a track to make sure it is moving freely.

If the motor still will not turn freely when mounted, try using a shim to move the front of the

motor up a bit from the gear.

Edited by - oldtimer52 on October 04 2016 2:19:56 PM

|

Country:  USA ~

Posts: 865 ~

Member Since: September 23 2014 ~

Last Visit: May 01 2023 USA ~

Posts: 865 ~

Member Since: September 23 2014 ~

Last Visit: May 01 2023

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 04 2016 : 2:44:33 PM Posted - October 04 2016 : 2:44:33 PM

|

I easily made some testing leads with some clips I bought at radioshack(a pack of 10 is around $2), and some electrical wire.

I put a clip on each end of a wire, and I made 2 of em.

Here what the clips look like:

If I can't fix it, I can fix it so it can't be fixed.

|

Country:  USA ~

Posts: 105 ~

Member Since: March 16 2015 ~

Last Visit: March 22 2023 USA ~

Posts: 105 ~

Member Since: March 16 2015 ~

Last Visit: March 22 2023

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 04 2016 : 2:47:01 PM Posted - October 04 2016 : 2:47:01 PM

|

Try spinning the motor armature(the coils) around with your finger. They should be really easy to spin.

Are they realy easy to spin?

If I can't fix it, I can fix it so it can't be fixed.

|

Country:  USA ~

Posts: 105 ~

Member Since: March 16 2015 ~

Last Visit: March 22 2023 USA ~

Posts: 105 ~

Member Since: March 16 2015 ~

Last Visit: March 22 2023

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 04 2016 : 8:05:15 PM Posted - October 04 2016 : 8:05:15 PM

|

I know what the clips for testing leads look like =P

Oldtimer, as I said in the post with the photo the wheels are able to turn freely.

Yes, the armature is easy to spin by hand. And when I fiddle it by hand, the worm gear turns the drive gear without issue.

Does anything appear to be at fault with the solder connection seen in the photo?

Feedback-hungry attention w****

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 04 2016 : 9:17:17 PM Posted - October 04 2016 : 9:17:17 PM

|

What I was getting at, does the wheels turn easy when the motor is attached and you use your fingers to turn the armature? The solder joint looks ok, but it should be very shiny. It seems

kinda dull which could mean a cold solder joint. I would reheat it to be sure of a good joint.

|

Country:  USA ~

Posts: 865 ~

Member Since: September 23 2014 ~

Last Visit: May 01 2023 USA ~

Posts: 865 ~

Member Since: September 23 2014 ~

Last Visit: May 01 2023

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 05 2016 : 06:16:12 AM Posted - October 05 2016 : 06:16:12 AM

|

There was something I stupidly forgot to check, and that was whether the connection was good at the other end of the wire. I tried actually soldering the wire to the brass connector, and that made a difference.

That revealed the problem to be two-fold:

The first problem was that the motor was only receiving a fraction of what the tender was picking up. That has now been solved.

The second issue is that despite appearances on the bench, the motor is not seated quite right and that's causing either binding or chassis power pickup issues. I'm going to try removing and re-seating it.

Feedback-hungry attention w****

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 07 2016 : 10:23:32 AM Posted - October 07 2016 : 10:23:32 AM

|

quote:Didn't mean to be hostile. Sorry

Now, I'm dead sure we have testing leads somewhere in the garage. It just... it bugs me somehow to have it assumed I'm using a specific kind of cable to power my track.

Originally posted by ZeldaTheSwordsman - October 04 2016 :  07:36:32 AM

|

It doesn't take formal test leads to test an engine, Swordsman. I cut and use wires of all types and sizes to test my engines. Of course, being in the Electronics/Computer field, I have access to tons of that stuff. But even around a household, you can find old power cords, speaker wire, and other copper wire with which to make "test leads" out of.  Unless you live in such a minimalist household, there are options out there. I guess we all just figured you could lay your hands on some wire around your house. Obviously having the nice clip type leads is great, too, but any small gauge wire will do the job of transferring electricity from a power pack to the engine directly. even the Bachmann E-Z track power wire I can use to test the engine with some ingenuity. Unless you live in such a minimalist household, there are options out there. I guess we all just figured you could lay your hands on some wire around your house. Obviously having the nice clip type leads is great, too, but any small gauge wire will do the job of transferring electricity from a power pack to the engine directly. even the Bachmann E-Z track power wire I can use to test the engine with some ingenuity.  , with some paper clips and such, you can rig up a way to touch the motor points to get it to fire up. It DOES take creativity to do so, though. , with some paper clips and such, you can rig up a way to touch the motor points to get it to fire up. It DOES take creativity to do so, though.

Jerry

" When life throws you bananas...it's easy to slip up"

Edited by - AMC_Gremlin_GT on October 07 2016 10:24:05 AM

|

Country:  USA ~

Posts: 3974 ~

Member Since: January 04 2009 ~

Last Visit: January 11 2019 USA ~

Posts: 3974 ~

Member Since: January 04 2009 ~

Last Visit: January 11 2019

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 07 2016 : 11:20:07 AM Posted - October 07 2016 : 11:20:07 AM

|

Sorry.

Anyway, the motor seems to be fine. With the tender connector soldered to the wire and the brass frame cleaned it's picking up power and turning as it should. There's just been binding issues with the rods that earlier tests didn't detect, been working on sorting those out.

Feedback-hungry attention w****

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 08 2016 : 10:25:12 AM Posted - October 08 2016 : 10:25:12 AM

|

quote:Sorry.

Anyway, the motor seems to be fine.

There's just been binding issues with the rods that earlier tests didn't detect,

Originally posted by ZeldaTheSwordsman - October 07 2016 :  11:20:07 AM

|

No problem.

Glad the motor is OK. In my troubleshooting method, I usually start at the motor brush contacts DIRECTLY first, and establish whether its' the motor itself, or something else. Obviously dirty armature pads, brushes loaded up with loose carbon, and dry armature shaft bushings are all problems with old engines. So I like to start at the motor, fix any issues there first by cleaning up those two parts, and oiling the bushings, then go from there. It's ALWAYS good to start with a cleaned and lubed motor anyway!

Binding can be hit or miss, too, so easy to miss at first. Anything from binding rods occasionally ( just need some lube at the joints ) to bent parts, which don't bind every revolution, can make it more difficult to troubleshoot. And like the guy said, sometimes the motor needs a shim to get it off the drive gear a bit. So lots to check on in this department.

Repairing trains is a challenge, not every problem is the same. And obviously takes a bit of troubleshooting sometimes when its not obvious what the problem is. Hope your engine is 'back on track" soon!

Jerry, train repair guy.

" When life throws you bananas...it's easy to slip up"

|

Country:  USA ~

Posts: 3974 ~

Member Since: January 04 2009 ~

Last Visit: January 11 2019 USA ~

Posts: 3974 ~

Member Since: January 04 2009 ~

Last Visit: January 11 2019

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 08 2016 : 11:00:46 AM Posted - October 08 2016 : 11:00:46 AM

|

It should be. I smoothed out the rods, got the motor shimmed.. At this point some added weight in the tender to make sure it's picking up well (with the other stuff out of the way I was able to determine that the tender pickup wasn't being as effective as it ought) and maybe a tiny bit more readjustment of the left-hand brush spring should do it (speaking of brush springs, I mangled one while upgrading my E7.. What's a good source of replacements?).

Feedback-hungry attention w****

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 08 2016 : 9:28:23 PM Posted - October 08 2016 : 9:28:23 PM

|

quote:(speaking of brush springs, I mangled one while upgrading my E7.. What's a good source of replacements?).

Originally posted by ZeldaTheSwordsman - October 08 2016 :  11:00:46 AM

|

Aurora has the correct flat BRUSHES for the PT motor. But not the brush springs. You need some of the older AF/X (slot car ) brush springs which are about 1/8 inch wide, and flat also. Not the long ones, won't fit. Edit - Oh , wait! You have the open-frame motor with the wire springs...welllllllllll, I don't know of a source for that type. AHM motors have a similar spring, might be able to get one of those to work.

Jerry

Jerry

" When life throws you bananas...it's easy to slip up"

Edited by - AMC_Gremlin_GT on October 08 2016 9:30:57 PM

|

Country:  USA ~

Posts: 3974 ~

Member Since: January 04 2009 ~

Last Visit: January 11 2019 USA ~

Posts: 3974 ~

Member Since: January 04 2009 ~

Last Visit: January 11 2019

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 08 2016 : 9:54:59 PM Posted - October 08 2016 : 9:54:59 PM

|

I think you got a bit confused there, Jerry :P My fault really since I suddenly switched to talking about a different engine

Feedback-hungry attention w****

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 09 2016 : 4:32:28 PM Posted - October 09 2016 : 4:32:28 PM

|

Although now it seems I could use a new one of the springs for the open-frame motor... and a new one of whatever that brown piece is on the top..

I've wound up breaking that in two places trying to get the brush back to how it was before I accidentally dislodged it (it's had too much wiggle room it feels like..). I've been having to fidget with it to get proper contact but of course that's only good for tests.. So I guess I did kill the motor...

And I apparently haven't been able to shim the motor right either because even when the motor is being properly powered it's not driving the wheels very well..

Feedback-hungry attention w****

|

Country:  USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024 USA ~

Posts: 750 ~

Member Since: December 05 2015 ~

Last Visit: January 24 2024

|

Alert Moderator

Alert Moderator

|

|

|

|

Posted - October 17 2019 : 6:55:13 PM Posted - October 17 2019 : 6:55:13 PM

|

Sorry to resurrect an old thread but I really want to see the paint scheme on that loco! The pink and red peaks my interest

|

Country:  USA ~

Posts: 1549 ~

Member Since: October 10 2019 ~

Last Visit: January 04 2024 USA ~

Posts: 1549 ~

Member Since: October 10 2019 ~

Last Visit: January 04 2024

|

Alert Moderator

Alert Moderator

|

|